After concrete is placed in service, unforeseen uses or conditions can affect its performance or...

Consider Lifecycle Costs for Concrete Restoration or Replacement

It seems obvious on the surface that repair or restoration of cracked or spalled structural concrete in a stadium, parking deck, bridge, tunnel, dam, dock or runway will reduce ownership costs. But if the underlying damage is severe, it may be more cost effective to tear down and rebuild.

A critical element in this evaluation is an assessment of overall lifecycle costs. This is the time-honored method to determine the best course of action with regard to structural concrete repairs. By considering all aspects of the financial equation, an owner can achieve a fuller understanding of available options. Spending a little more today to fix an immediate problem correctly may considerably reduce the total cost of the structure over its lifespan.

“Life cycle costs (LCC) are cradle to grave costs summarized as an economic model of evaluating alternatives for equipment and projects,” said H. Paul Barringer, P.E. of Barringer & Associates. Inc. “The objective of LCC analysis is to choose the most cost effective approach from a series of alternatives to achieve the lowest long-term cost of ownership.”

Concrete Condition Survey

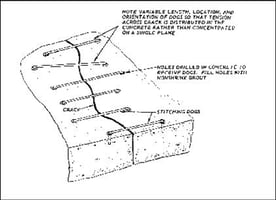

Identifying unseen conditions and the extent of damage is a key element in any LCC evaluation. Non Destructive Testing (NDT) is often used by engineers to obtain detailed structural information. NDT techniques include sounding, galvanic pulse testing, ground penetrating radar and in-situ load tests. When more upfront condition detail is available, the engineer can prepare a more accurate remedial cost estimate and it is less likely the owner will face costly change order surprises should he elect a repair option.

A huge repair bill may tilt the balance towards replacement as is the case with some older hospitals in California where state regulations require emergency buildings to meet current more stringent earthquake codes. A major healthcare provider in Los Angeles, for example, recently demolished two large buildings erected around 30 years ago and is rebuilding. The high cost of improving the structural elements of these facilities to meet current seismic standards was one of several factors which led management to select the replacement path.

In some cases, replacement may prove to be the better option for an older structure with only a few years left before the design life ends. In all instances, it is prudent to hire an engineer for a structural lifecycle evaluation and condition survey. If the damage is not disruptive to the entire structure, often the best option is to repair.

Take the case of San Francisco Airport, which has taxiway lights embedded in concrete structures. When the concrete collars for these lights began to fail, the airport tried a quick setting cementitious repair material which failed to eliminate the problem. Faced with a live heavily used aircraft taxi lane, it considered all options for further repair or complete replacement. In this case, it chose a proven solution capable of being injected in harsh loading conditions: a customized epoxy formulated specifically to cope with the difficult working conditions and without compromising concrete integrity. “The ChemCo epoxy stabilized our taxiway lights and eliminated further deterioration,” said Charlie Freas, a civil engineer at San Francisco International Airport. “This proved to be the right decision in the long term, both financially and structurally.”

The airport has since used similar epoxy formulations to repair cracking in parking structures, service tunnels below groundwater level, and the airport’s light rail system, as well as for concrete spalling on taxiway aprons and ramps.

With regards to pavement concrete spall repair, the airport is constantly inspecting its runways, aprons, and the surrounding concrete infrastructure for any signs of degradation in order to avoid flying object damage (FOD) which can cause catastrophic damage to jet engines. “As concrete spalling can be substantial at times and the consequences so significant, we would rather replace an entire concrete section than be faced with the possibility of having to buy a new airplane engine,” said Freas. “However, we have confidence that effective epoxy spall repairs provide the flexibility and strength to support our planes without further spalling.”

Factors to Consider for Concrete Restoration

Freas pointed out that lifecycle costs may not be the only factor to take into account when it comes to the repair versus replace question. In some instances, the airport needs to realign a runway or change the grade, at which point all associated concrete areas may be completely removed and replaced.

Similarly, the Port of Oakland in California has to look beyond the subject of lifecycle costs for certain structures. One tenant, for instance, utilized an 80-year-old wharf complex for container crane operations. While the wharf clearly needed to be rebuilt, the port had no temporary site available. Repair was the only possibility.

Similarly, the Port of Oakland in California has to look beyond the subject of lifecycle costs for certain structures. One tenant, for instance, utilized an 80-year-old wharf complex for container crane operations. While the wharf clearly needed to be rebuilt, the port had no temporary site available. Repair was the only possibility.

Another time a tenant dropped a 60-ton piston from a height of 100 feet onto a wharf resulting in severe damage. In this case, lifecycle costs favored repair. The port harnessed epoxy injection for concrete crack repair of the wharf deck and soffit (underside). “I’ve inspected the wharf below sea level and the ChemCo Systems customized epoxy prevented any corrosion of the rebar, returned the structure to its original strength and extended its lifespan,” said Bill Morrison, Manager of Harbor Facilities for the Port of Oakland. “After many years, these wharves are still operating as designed.”

Repurpose for Changing Times

A recent fast-growing trend is to find and adapt new uses for vacant buildings or structures that have remaining useful life. Governments world-wide are passing new regulations and may offer monetary incentives to recycle or adaptively reuse existing buildings rather than choosing demolition. This is already happening widely in the U.S. where the practice is often referred to as brownfield redevelopment. In China’s large cities, owners are rewarded with financial incentives if they agree to convert an old hotel into condos or an aging office structure into a warehouse. Several former parking decks have been transformed into computer server farms in Beijing after exterior shells were revamped.

This repurposing trend for existing buildings is a high growth element of the sustainable construction movement and is beginning to eclipse new construction in urban areas of North America due to architectural preservation, environmental and waste disposal concerns.

Whether you elect to repair, restore or replace concrete, do it right, select the correct materials and consult an engineer who can help you evaluate your options from a lifecycle perspective. Call or email us at ChemCo Systems if you need help with concrete restoration, repair or protection.